For accurate and reproducible science, it is vital to prioritize sample integrity. The integrity of samples can be compromised at all stages of sample handling, from initial collection to storage, and sample separation is no exception.

Sample separation refers to purification and cleanup. Collected fractions from the purification process, or eluates from cleanup, must remain an accurate representation of the original sample. Fundamentally, this means that no compounds can be lost from or added to a sample. During sample separation, however, there is a significant risk of sample losses and contamination sample — often due to the equipment used or the nature of the sample itself.

Using the right systems can improve sample integrity, helping labs to have greater confidence in their results. Here we outline what to look for in your sample separation instruments to remove risks of common threats to sample integrity.

The Purification Challenge

Purification is a necessary step of workflows in new compound research and development, whether labs are working on synthetic samples or natural products. For the majority of applications, it is of the utmost importance that you can obtain your compound(s) of interest from a complex sample by maximizing rate of recovery and purity, thereby accelerating the productivity and profitability of your workflow. But often, this comes at the expense of throughput, limiting productivity.

There are, unfortunately, challenges to maintaining sample integrity and productivity during the purification steps, owing to inappropriate or substandard equipment. Notably, irreversible adsorption or sample precipitation can occur, meaning quantities of valuable samples are lost and require remaking. Not only does this increase costs, but it also requires significant additional time investment — needing lab personnel to make up potentially years of lost work depending on the samples affected.

Even if your compound avoids separation traps, purification can also fall flat at the next hurdle: knowing what fraction(s) your product is in. Choosing the right purification system is, therefore, crucial to correctly identify where your product is and maximize recovery.

Choose the Right Sample Separation System

A range of purification solutions are available, including centrifugal partition chromatography (CPC) which is well suited for complex samples, such as natural extracts as CPC offers silica-free purification, or high-performance liquid chromatography (HPLC), well described for most applications.

Often, multiple options can be available for your application. In these instances, additional research — either online or in the lab — can help identify the right solution for you. So, what else should you consider in an HPLC purification system?

- Automation

Even the best trained lab personnel can be a source of contamination during purification. An automated system will benefit your workflow as it minimizes human input, thereby reducing contamination and leading to more reliable and reproducible data. As an added bonus, automated systems can feature pre-programmed methods and sample queueing capabilities, allowing for sharing of the instrument by a pool of users.

- Efficient Injections

In purification workflows, losses can occur even at the injection stage. To minimize the risk of losses due to sample precipitation, look for a system where the sample is injected directly into the heart of the valve and can be equipped with large sample loop flow path. Additionally, an instrument that can dilute the sample prior to injection avoids concentrated samples running through the tubing and reduces the risk of precipitation.

- High Pressure Gradient Pumps

A pressure spike can occur when the sample reaches the column, as the sample can precipitate to the top.

A high-pressure pumping system can help manage the pressure spike, delivering a reproducible elution gradient that guarantees a consistent retention time for peaks.

- Detection

Lack of compound traceability hinders purification, leading to lower recovery of the sample. Find a customizable system that enables traceability: modern systems, for example, produce chromatograms clearly indicating which tube your compound is in. Several different compound detection options are available: ultraviolet-visible (UV/vis), evaporative light scattering (ELS) and mass spectrometry (MS) detectors can all be used depending on your need. The detection mode will then trigger fraction collection, enabling you to maximize recovery and purity.

For further security, you can use multiple detection methods at once. Universal detectors such as ELS can show most of the sample content, and when stacked with targeted detection such as MS you can ensure that you are collecting the right compound.

- Secure Fraction Collection

If the system uses a shared path for injection and fraction collection, there is the possibility that the injected sample can contaminate a purified fraction, reducing sample integrity. When choosing a new system, look for one that segregates the injection fluid path and collection fluid path with a HPLC valve and valve actuator to avoid potential cross-contamination.

- System Controls

Not to be overlooked, software usability is essential to stay in control of purification and ensure sample integrity. Look for a system that gives you full control of the injector and fraction collection to improve sample purity. Additionally, being able to perform manual actions, such as changing gradients, is vital to enable the best recovery of samples.

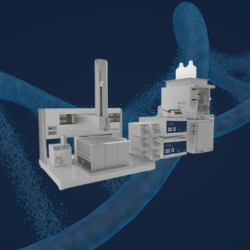

Gilson VERITY® Systems

Obtain your desired compounds in high purity with Gilson’s VERITY® systems —flexible and automated solutions to LC purification from the milligram to the multigram scale. The instruments feature a one-way fluid system with no cross-contamination, directly injecting your sample into the heart of the valve for improved sample integrity. What’s more, they are fully automated, offering flexible reporting capabilities and sample traceability for maximum recovery.

Find Our Systems

The Cleanup Conundrum

Sample cleanup is a mandatory step to achieve reliable analytical results across laboratories from environmental testing to food safety, but it comes with the potential for compromised sample integrity. Significantly, both cross-contamination and leachables can affect sample integrity, leading to false positives in data. But cleanup can also lead to sample loss, meaning a lack of precision and sensitivity due to insufficient quantities of the sample for reaching the limits of quantification and detection.

To maintain sample integrity during cleanup, several key factors need to be considered:

- Avoid sources of cross-contamination. Cross-contamination can occur from both the environment and the instrument, so ensure both are kept clean.

- Minimize the sources of losses. Improving compound recovery means that any compound loss needs to be minimized, which can be achieved by controlling key parameters of the cleanup process. Solid phase extraction (SPE), for example, is dependent on the loading flow rates, contact time, and the drying state of the packing material.

- Improve reproducibility. Manual procedures can be particularly hard to standardize due to inadvertent human error. However, the sample itself and its viscosity can also have a strong impact on reproducibility. Finally, the protocol itself can be difficult to reproduce if it is long and complex, such as fractionation or multi-dimensional SPE.

Choose the Right Cleanup System

As with purification, it is imperative to choose the right system for your needs. SPE can be used for most routine applications where yield, reproducibility and accuracy are important. When selecting a system, four factors should be considered:

- Automation

Switching to an automated system reduces manual intervention and thereby lowers the risk of sample loss. Additionally, automated systems can improve your operational flexibility, as they are highly adjustable to meet the specific needs of your lab. You don’t need to automate all parts of the clean-up, either — guides to help you bring in aspects of SPE automation are available so you can reap the most benefit.

- The Materials Used

Specific compounds, such as those found in fluoropolymer tubing, can contaminate systems that isolate perfluorinatedcompounds. You should look for a flexible system with interchangeable high-quality tubing, as this will reduce contamination from leachables and limit potential compound adsorption, too.

- The Probe

Often, systems will feature disposable tips as they tend to eliminate the risk of cross contamination. However, disposable tips increase operating cost and lab waste. Choosing a system with a washable probe can offer a more sustainable alternative while still reducing contamination.

- Closed Vial Compatibility

Much of the contamination risk comes from volatile compounds in the environment, so you should select a system that works with closed vials to keep the compound sealed away from the environment. Working with closed vials further protects sample integrity by avoiding evaporation of the samples before extraction.

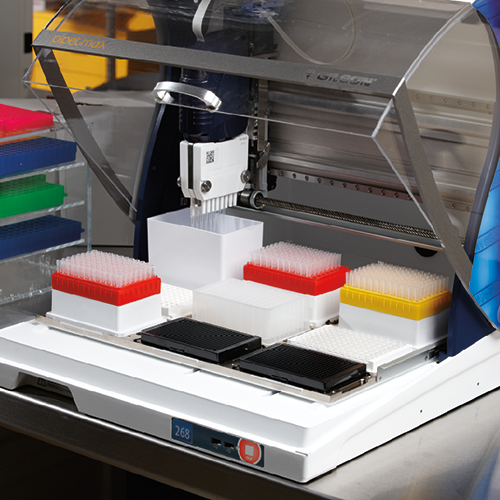

ASPEC® 274 SPE System

Gilson’s ASPEC® 274 system is a positive pressure SPE that improves sample integrity during clean-up by producing more reliable and reproducible data. What’s more, it can aid technically challenging and repetitive processes to limit operational disruptions and simplify your workup. The system features:

- Perfect control of SPE key parameters for minimizing sources of losses

- Scaling capabilities, handling sample volumes from 0.1 mL to a liter

- A washable probe combined with Liquid Level Following and specifically-designed rinse stations

- The highest quality materials in its construction, with interchangeable tubing

- Protection from environmental contamination due to the ability to use closed vials

- A syringe pump pressure-sensing module that monitors pressure on each fluid path individually to automatically supervise error handling and alerts you to problems such as high cartridge pressure and clogged liquid lines

Request A Quote

The Right Systems for Confident Sample Purification and Cleanup

It is vital that you perform your purification and cleanup procedures correctly to maintain your sample integrity. But your workflows should be simple and flexible, too, with maximum productivity and profitability. Understanding the available options — and selecting the right instrument — will give you confidence in your sample while helping you smooth your processes. What’s more, automating your sample separation is the key to ensuring your processes are reproducible, reliable, transferable, and productive.

Gilson offers a range of solutions to improve the integrity of your sample separation. See how our ASPEC systems can be used to extract perfluorinated compounds from tap water, or learn more about how to find the right HPLC system for your purification needs.